Lighting

The device makes use of special lighting to produce a white box effect, which lights up the bottles evenly from all sides, providing a surround-view of a bottle and all its areas.

Camera

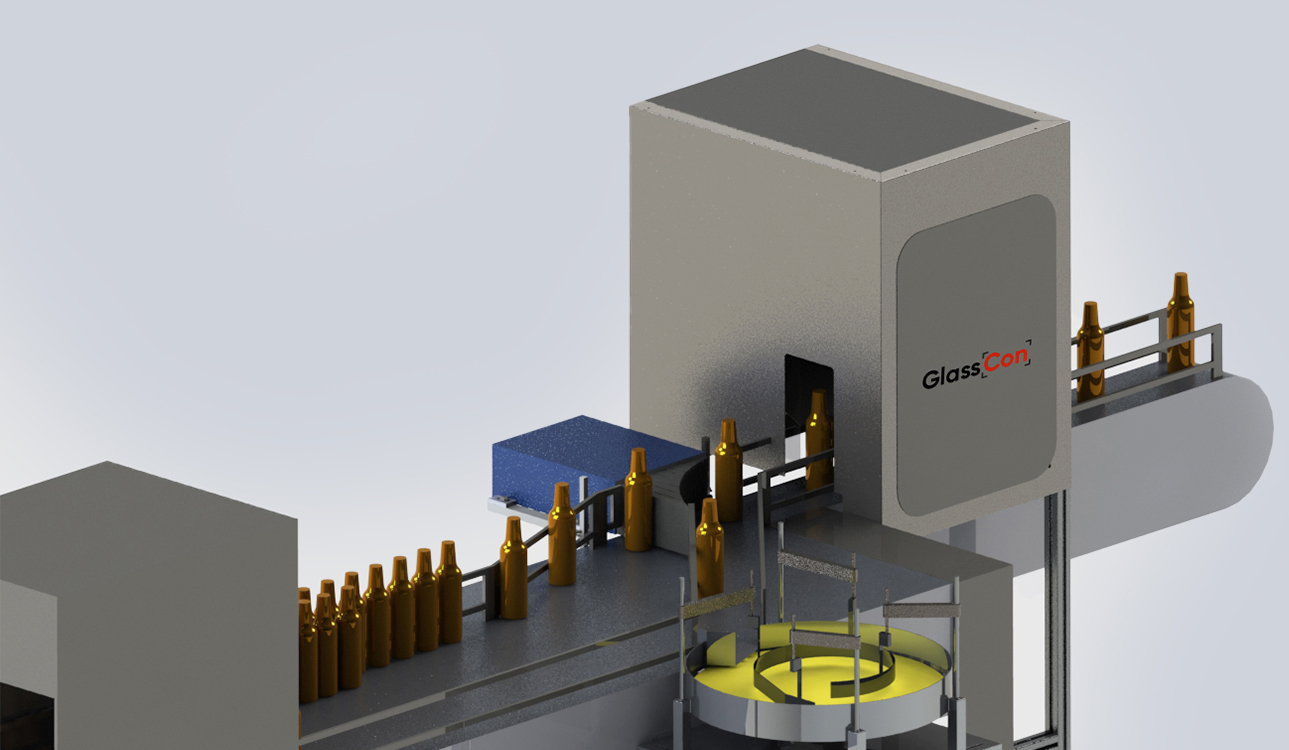

The GlassCon Bottle Quality Control System is a unique quality and analysis control system that can perform a complete 360-degree analysis of a bottle and its elements using only a single high-resolution camera.

The mirror system

This is possible because the technology uses a uniquely configured 4-mirror system, which allows the user to view the whole bottle, as well as its neck and cork areas from above in one image. The reflections of the mirrors are placed so that the camera can do this by filming just one of the mirrors and not the bottle itself.

Control panel

The device is simple to use – it uses a modern, user-friendly app that can be controlled via the machine’s control panel. The device requires no additional interaction. Light control, for example, (on / off) is automated at the start of a session.